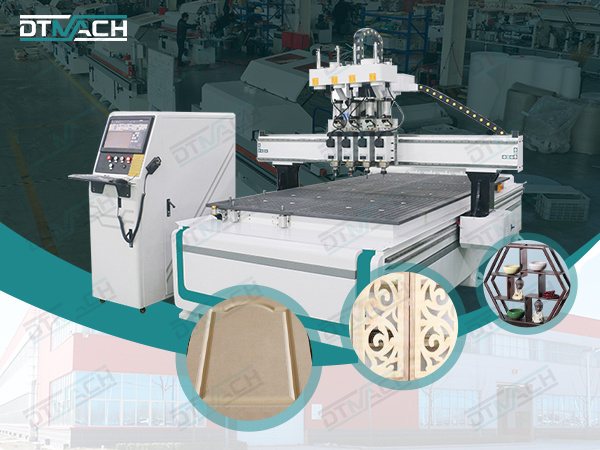

FULLY AUTOMATIC LOADING AND UNLOADING CUTTING MACHINE

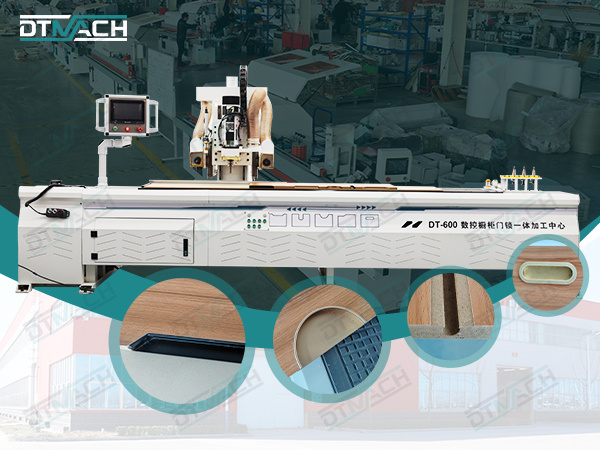

Fully automatic loading and unloading cutting machine, inline atc cnc wood router for mdf cutting wood furniture cabinet door making. Automatic tool change and automatic tool setting.

- Video

- Product Description

- Parameter

- Advantages

-

- Commodity name: FULLY AUTOMATIC LOADING AND UNLOADING CUTTING MACHINE

Fully automatic loading and unloading cutting machine, inline atc cnc wood router for mdf cutting wood furniture cabinet door making. Automatic tool change and automatic tool setting.

Key words:- FULLY AUTOMATIC LOADING AND UNLOADING CUTTING MACHINE

-

-

DETAIL PARAMETERS

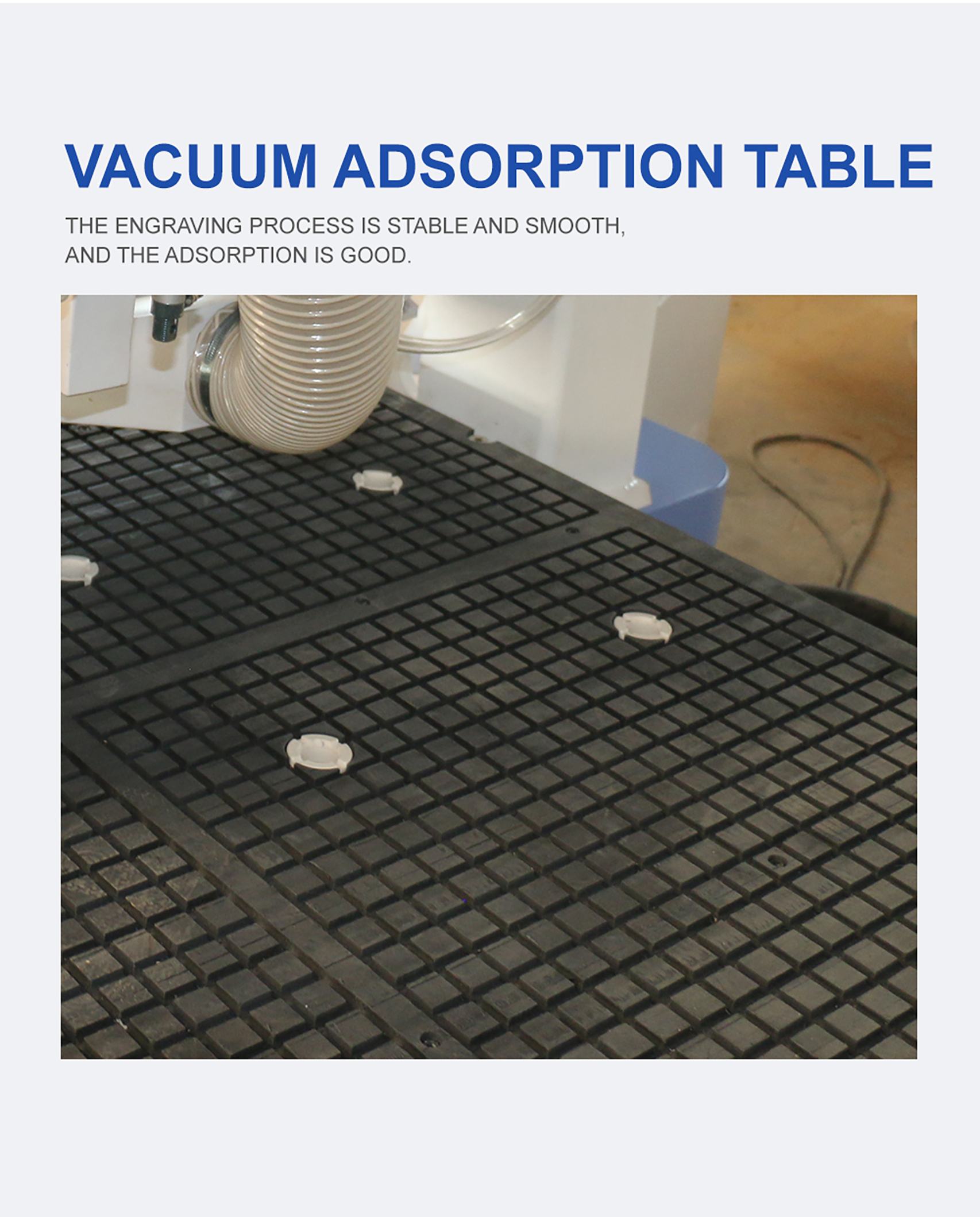

Voltage 380V 3PH60HZ Inverter 11KW Max empty travel speed XY50000mm/min Z20000mm/min Working Speed 15000-30000mm/min Countertop structure size Vacuum Adsorption

Countertop:1260*2480mm 24holes

Bed structure Heavy Bed Structure Transmission Guide ;25mm Square rail Spindle power 9KW Air cooling Spindle speed 0-18000rpm Drive motors 1500W servo motor Dust collection 5.5KW Vacuum Pump 7.5KW water pump Total weight 2.5t -

1 .Atc automatic tool change spindle--adopts air-cooled spindle, high speed and high working efficiency.

2. Vacuum adsorption table--the engraving process is stable and smooth, with good adsorption, making the cut material smoother and the engraved pattern more delicate.

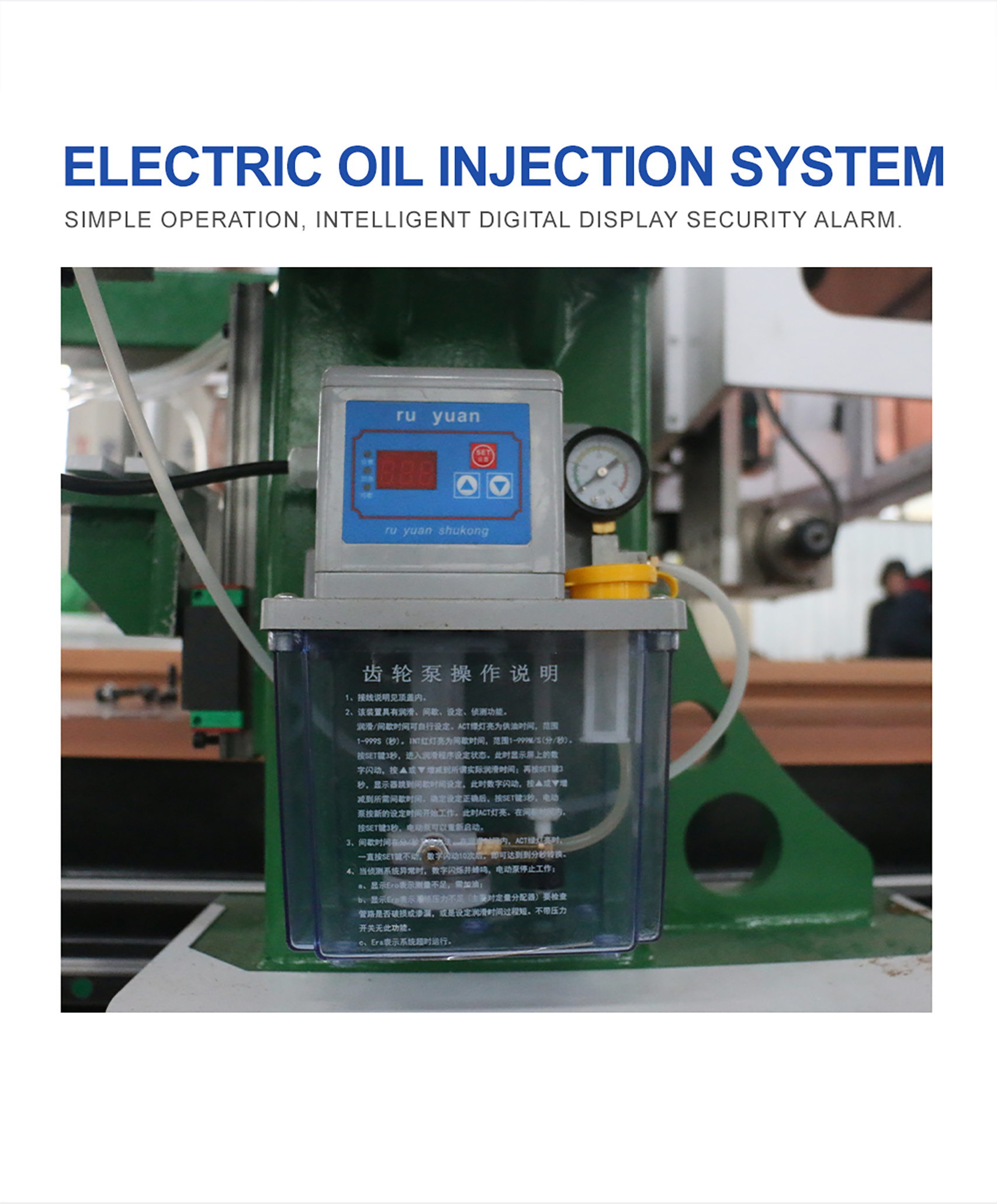

3. Electric oiling system--simple operation, intelligent digital display safety alarm. The automatic oiler can ensure the lubrication of the sliding screw guide rail according to the time.

4. Automatic replacement of tool heads--No need to manually replace tools when the machine is working. Save a lot of time and improve efficiency.

5. Automatic tool setting - reduce manual errors and improve production efficiency. The automatic tool setting system can more accurately locate the tool position, ensure processing accuracy and quality, and is easy to use.

6. Blade head--High hardness, precise cutting of various plates, reducing noise and improving durability

7. Transmission link--a combination of high-end imported precision components, running "fast" while engraving accurately

8. Control system--We use Taiwan LNC control system, the quality is very stable. Specially used for furniture production.

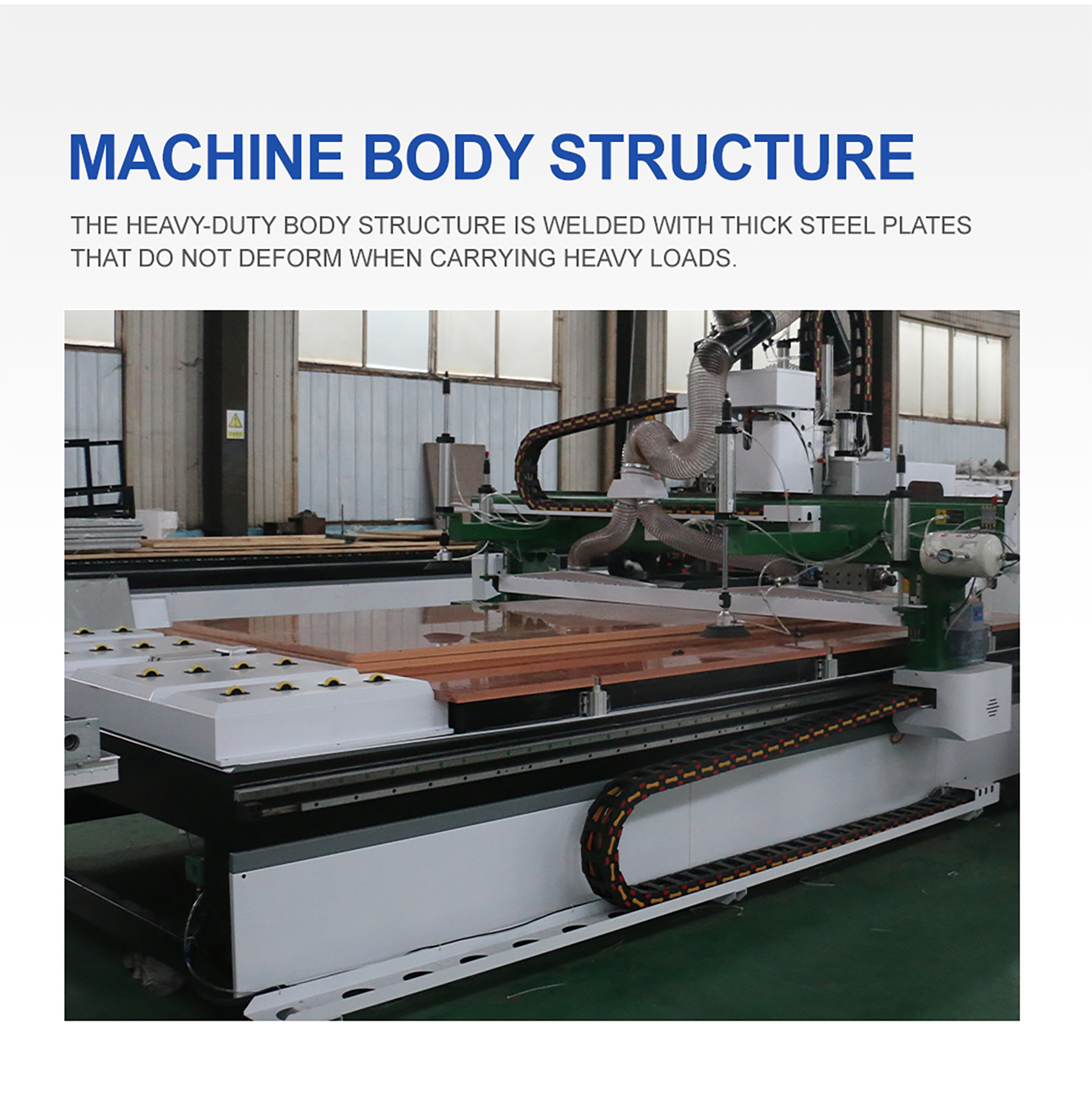

9.Bed structure--The heavy-duty body structure is welded with thick steel plates, and will not deform when carrying heavy objects.

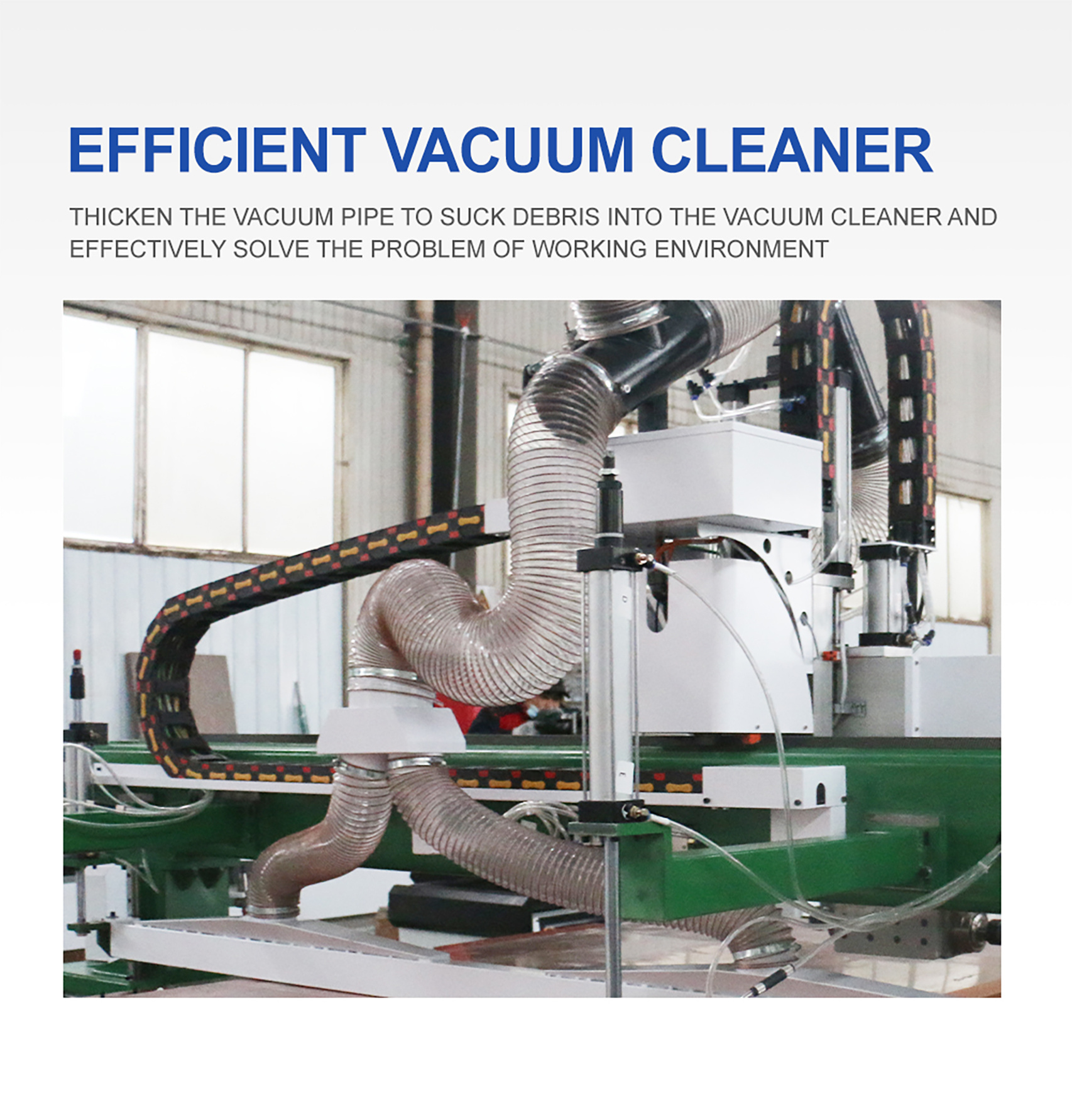

10. Dust suction port - efficient dust suction device, thickened dust suction pipe, sucking debris into the dust collector, effectively solving the problem of working environment

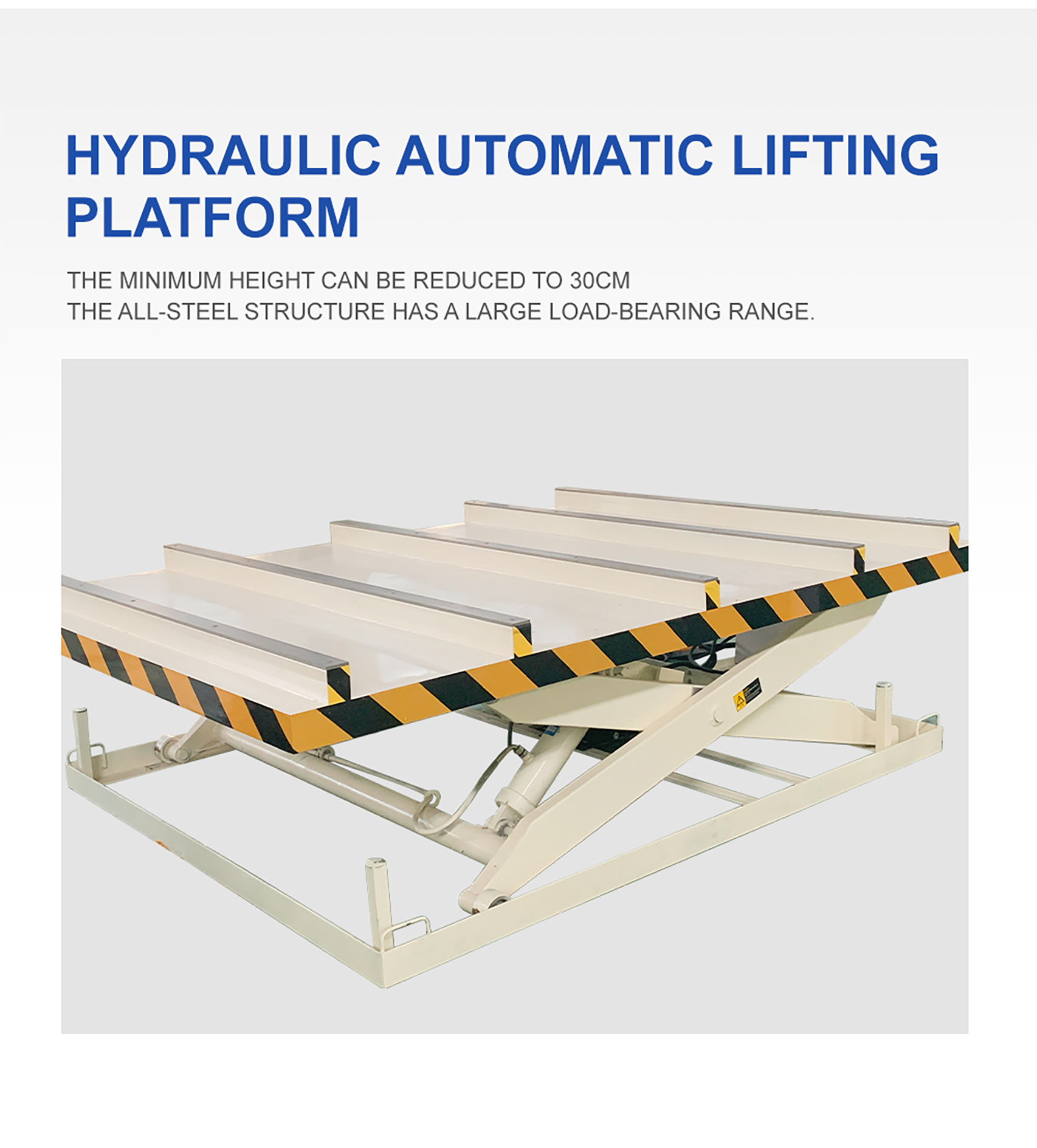

11. Hydraulic loading platform--Hydraulic automatic lifting platform, the minimum height can be reduced to 30CM for fully automatic production, and the all-steel structure has a large load-bearing range.

12. Conveyor belt unloading--Conveyor belt unloading system saves time for manual picking, realizes full automation, and effectively reduces labor costs

Previous:

Next:

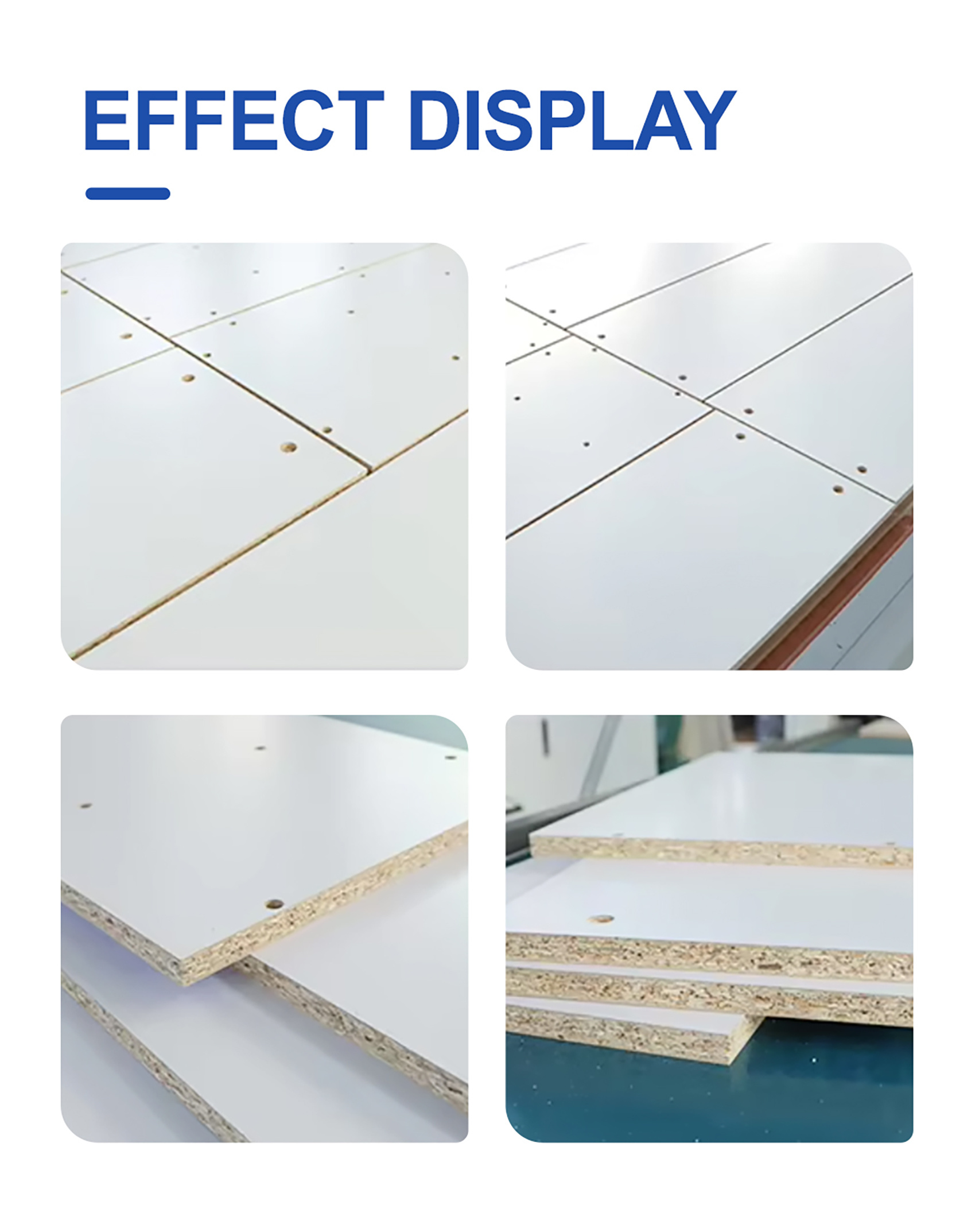

Effect Of Sheet

Related Products

Products Message

Please fill in the form with your details and we will get back to you as soon as possible