07

2025

-

06

Essential for custom furniture: How does the special-shaped edge banding and trimming machine achieve complex shape processing?

Unveiling the secrets of KN-700-3: efficient, precise, and intelligent, it solves the problem of edge banding and trimming of special-shaped panels!

Author:

In the custom furniture industry, the edge banding of special-shaped panels has long been a problem for production efficiency and quality. As a factory that has been deeply involved in edge banding technology, we have launched a revolutionary product - the KN-700-3 fully automatic edge banding and trimming machine. With dual-function integrated design and intelligent control system, it completely solves the processing problems of complex shapes such as circles, ovals, and rounded rectangles, and provides full-link precision guarantee for high-end customization.

**Analysis of the core technical advantages of KN-700-3:**

1. Intelligent edge banding, accurate and efficient:

* Laser ranging, accurate to the millimeter: Advanced laser ranging technology is used for panel docking to ensure the edge banding seam, and the error is strictly controlled within ±0.3mm, achieving nearly perfect seamless docking and greatly improving the appearance quality of the product.

* Super large glue pot, double glue compatibility: Equipped with **2600ml super large capacity upper glue pot, it significantly reduces the downtime of frequent glue addition and improves the efficiency of continuous operation. Supports PUR/EVA dual-use glue to meet different bonding strength and process requirements. One-touch glue removal function, more convenient glue replacement and cleaning.

* Flexible adaptation, intelligent storage: The edge banding head can be rotated 15 degrees, which can easily adapt to the edges of special-shaped boards with various angles and curvatures to ensure uniform and firm gluing. Up to 20 commonly used board data (thickness, length, curvature, etc.) can be pre-stored, which is quick to call and more intelligent for production switching.

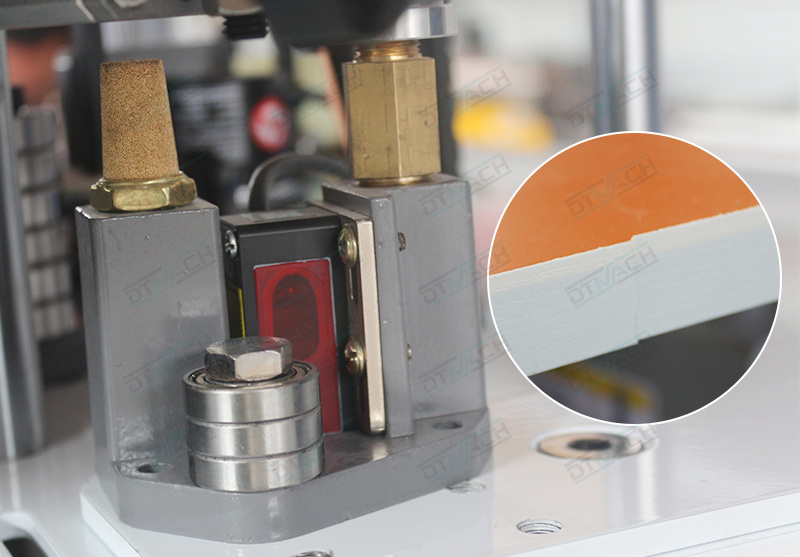

* Intelligent pressing, stable and reliable: With automatic acceleration and deceleration function, it ensures the consistency of edge banding quality under different feed speeds. Secondary auxiliary pressing technology, the edge banding strip and the board are pressed twice to enhance the firmness of the adhesive.

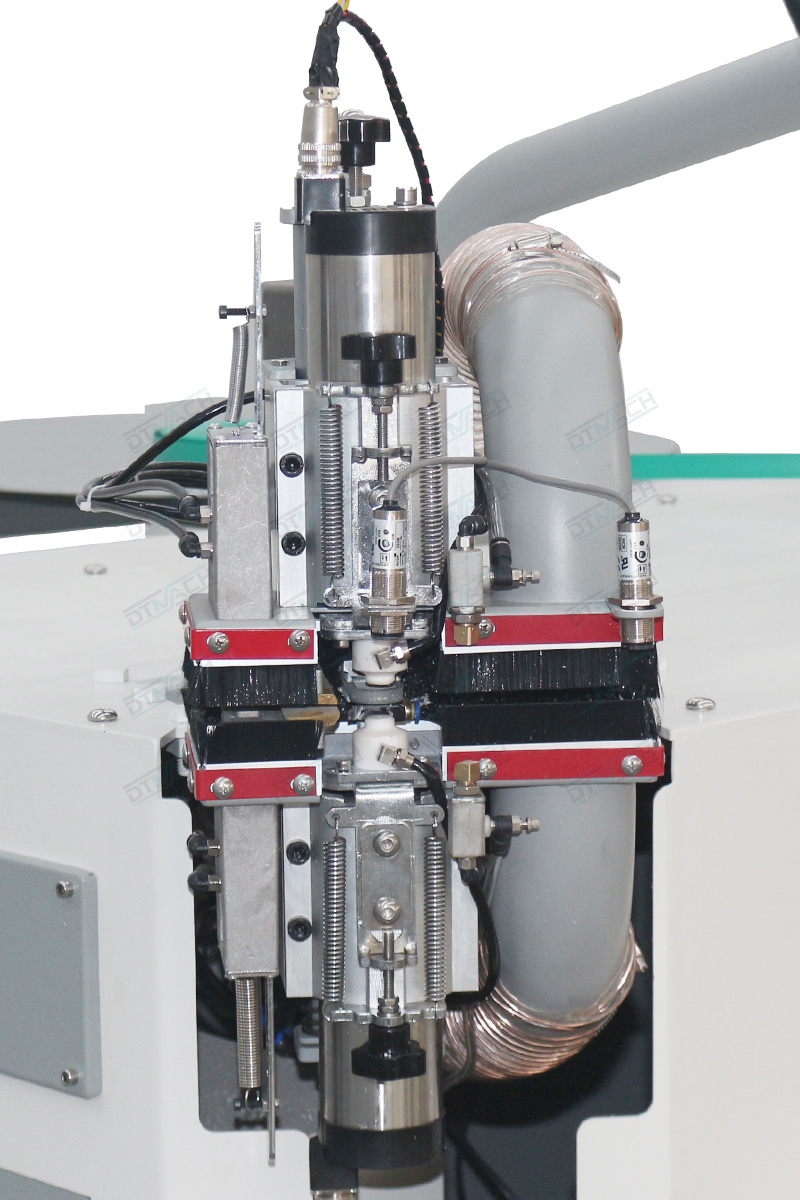

2. Intelligent trimming, one-step:

* No thickness adjustment, worry-free and labor-saving: Innovative design realizes the function of no thickness adjustment for trimming boards! The equipment automatically adapts to boards of different thicknesses, eliminating tedious machine adjustment steps, improving production efficiency and lowering the operating threshold.

* Automatic glue removal, clean and efficient: The integrated automatic glue spraying system can effectively soften the residual glue before trimming, significantly improve the life of the trimming tool, and ensure that the trimming surface is clean, smooth, and free of glue marks.

* Upper and lower trimming, follow-up scraping: The upper and lower edges are trimmed simultaneously, and the verticality and smoothness of the edges are completed at one time. The follow-up scraping function closely follows the contour of the special shape, ensuring that complex parts such as arcs and corners can also obtain uniform and smooth trimming effects, presenting exquisite and perfect edge banding details.

**Source factory, quality assurance**

As the **source factory** that has been deeply involved in the field of edge banding equipment, we always adhere to independent research and development and lean manufacturing. The KN-700-3 edge banding and trimming machine embodies our deep understanding and continuous innovation of special-shaped processing technology. Its excellent performance, stable performance and thoughtful design have won the trust and selection of many well-known custom furniture companies.

**Contact us now to learn more about the KN-700-3 special-shaped sealing and repairing machine, and start a new era of efficient and accurate special-shaped sheet processing! **

Related news

2025-05-15