07

2025

-

08

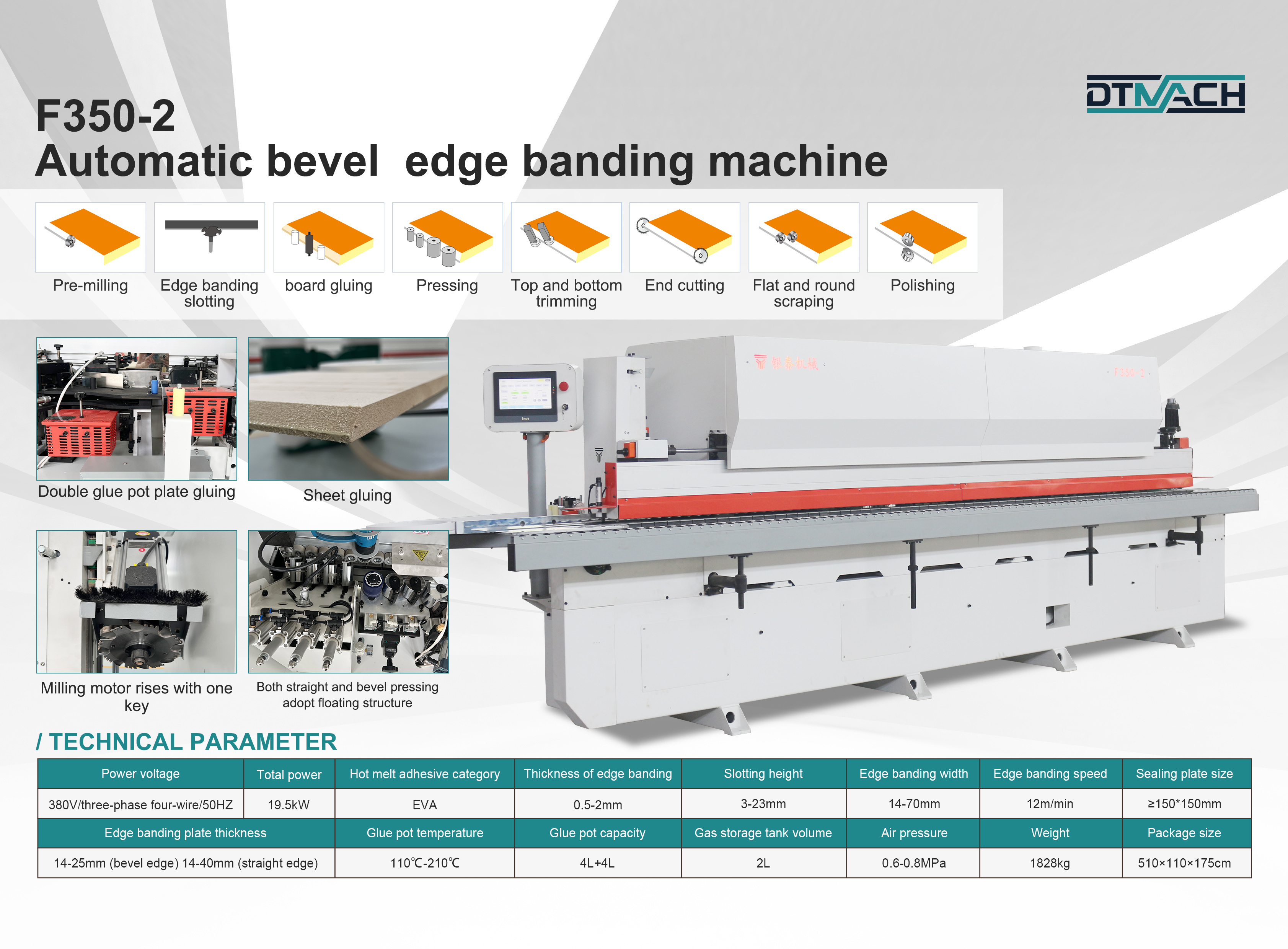

F350-2---A brand new linear edge banding machine for panel furniture

F350-2 is a fully automatic straight edge banding machine that can seal two types of panel shapes, 45-degree beveled straight edge and straight edge. Our new edge banding machine is designed to meet the changing needs of modern furniture manufacturers - faster, smarter and more efficient than ever before.

Author:

F350-2 is a fully automatic straight edge banding machine that can seal two types of panel shapes, 45-degree beveled straight edge and straight edge, and the machine uses panel glue to make the edge banding and panel fit more firmly. Our new edge banding machine is designed to meet the changing needs of modern furniture manufacturers - faster, smarter and more efficient than ever before.

Main features of F350-2 edge banding machine

1. Sturdy structure

The machine is made of high-strength structural steel, and is rust-proofed and electrostatically sprayed to ensure long-term stability in harsh environments.

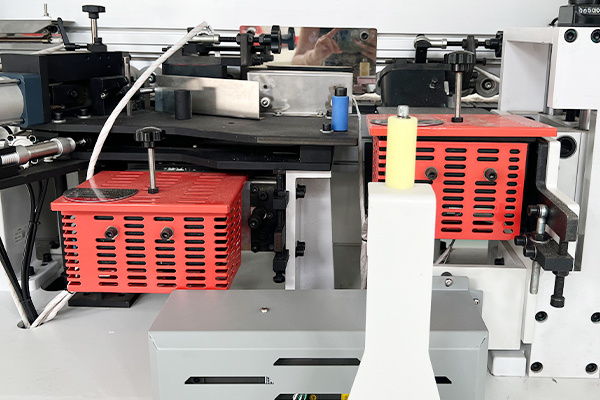

2. Gluing part

The machine uses double glue pots (4L+4L), corresponding to 45-degree beveled straight edge and straight edge respectively, and the large-capacity glue pot avoids multiple glue additions. And a new panel glue assembly is used to make the edge banding firmly adhered.

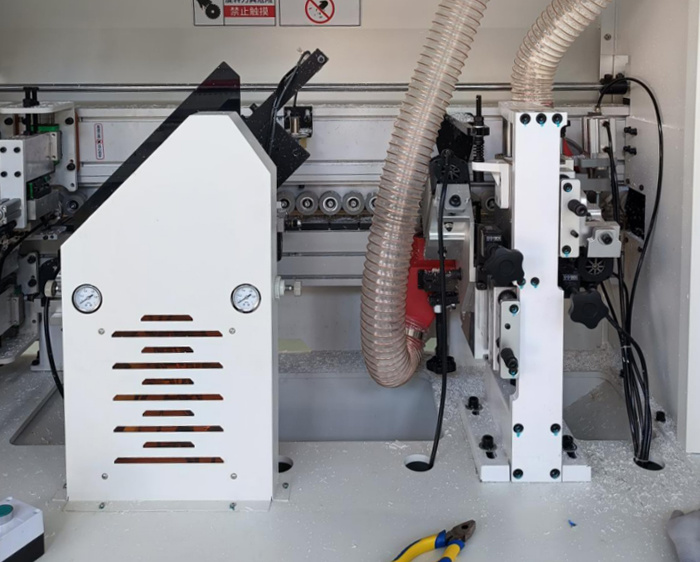

3. Pressing part

(1) The machine uses 4 straight pressing passes and 4 inclined pressing passes, all of which adopt a floating structure, making the edge banding more firmly pressed and strong.

(2) Hot air and heating lamps are used to assist in softening the edge banding and increase the bonding force.

(3) The cylinder controls the pressing wheel to switch to different positions to process different shapes of plates.

4. Trimming part

The machine first trims the edges and then trims the ends to avoid edge collapse of the edge banding. The trimming part uses upper rough trimming and lower fine trimming, and the upper and lower contouring positions are adjustable to achieve better trimming effect. When switching shapes, the cylinder automatically switches to achieve the switch between straight edge and 45-degree oblique straight edge trimming.

Other advantages:

Straight edge plates are directly milled into 45-degree oblique straight edges.

Applicable plate thickness: 45-degree straight edge plate thickness 14-25mm, straight edge þplate thickness 14-40mm, processable plate size: ≥150*150mm, one-button setting (electric lifting).

The milling motor rises with one button, the tool is easy to replace, can be repaired, and has a long service life.

Automatically spray the glue remover, remove glue at both edge sealing and trimming, not easy to stick to glue, clean and tidy.

Related news

2025-05-15