15

2025

-

04

Introducing the JC510 Soft-Forming Edge Banding Machine: Revolutionizing Precision and Efficiency

The JC510 Soft-Forming Edge Banding Machine is engineered to elevate productivity and precision for furniture manufacturers. Its unmatched versatility, patented milling accuracy, and user-centric design empower businesses to meet complex customization needs while reducing operational costs.

Author:

The JC510 Soft-Forming Edge Banding Machine is a cutting-edge, fully automatic solution designed for both straight and soft-forming edge banding applications. Combining advanced technology with user-friendly features, the JC510 redefines precision, versatility, and productivity in the production of lacquer-free handleless cabinet doors and panel processing.

Key Features of the JC510 Edge Banding Machine

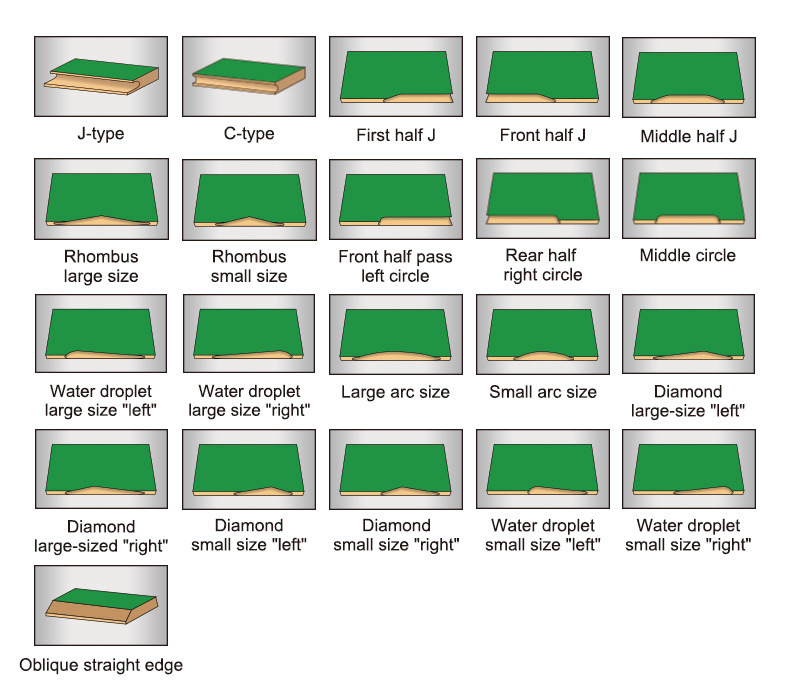

1.21 Crafted Profiles in One Machine

The JC510 supports 21 distinct edge profiles, including straight edges, full-through J/C shapes, semi-through J-shaped profiles (front/middle/rear), diamond (large/small left/right), partial arcs (front/middle/rear), teardrop (large/small left/right), rhombus (large/small), and rounded arcs (large/small). This versatility eliminates the need for multiple machines, streamlining production for diverse design demands.

2.Patented Precision Template Milling (Patent No.: 202323345535.6)

Equipped with an innovative "Precision Template" system, the JC510 achieves milling accuracy ≤0.2mm, ensuring flawless alignment for left/right door panels. The integrated lubrication system enhances durability and smooth rail operation.

3.High-Speed Efficiency

With a processing speed of 9 meters per minute and compatibility with 18mm, 22mm, and 25mm thick panels, the JC510 maximizes throughput while maintaining consistency.

4.21.5-inch Touchscreen Control

The intuitive 21.5-inch HD touchscreen allows operators to switch profiles and panel thicknesses with a single tap, simplifying setup and reducing downtime.

5.Robust Construction

Built from high-strength structural steel with anti-rust treatment and electrostatic spraying, the machine ensures long-term stability in demanding environments.

Advanced Systems for Superior Results

1.Dual-Purpose Glue Application

The fast-adhesive melting pot system enables quick glue application and one-touch glue discharge for effortless maintenance.

2.Enhanced Pressing Technology

3.Independent Straight-Edge Pressing: Strong clamping force ensures seamless adhesion.

4.Thermal/Cold Forming Chamber: Adjustable temperature settings guarantee consistent, bubble-free bonding.

5.Automatic Cleaning & Finishing

6.4-Point Glue Removal: Auto-spray cleaning agents prevent residue buildup.

7.Pre-Trimming & Crushing: A pre-cutting system trims excess edges via rotary blade crushing.

8.High-Precision Trimming: Multi-tooth saws and R-corner finishing ensure smooth, flush edges.

9.Scraping & Polishing: Automated scraping eliminates tool marks, while polishing delivers a flawless surface.

Why Choose the JC510?

The JC510 Soft-Forming Edge Banding Machine is engineered to elevate productivity and precision for furniture manufacturers. Its unmatched versatility, patented milling accuracy, and user-centric design empower businesses to meet complex customization needs while reducing operational costs. Whether crafting high-end cabinetry or modern panel designs, the JC510 delivers smoother workflows, superior finishes, and a competitive edge.

Related news

2025-05-15